NDT

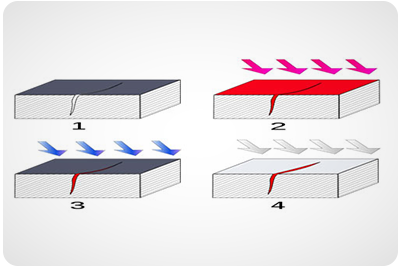

Liquid penetrant inspection is drawn into the surface-breaking crack by capillary action and excess surface penetrant is then removed; a developer (typically a dry powder) is then applied to the surface, to draw out the penetrant in the crack and produce a surface indication.

Magnetic particle inspection (MPI) is a relatively simple concept. Magnetic flux leakage testing and visual testing. ... Any place that a magnetic line of force exits or enters the magnet is called a pole.

Ultrasonic thickness gauging (UTG) is a widely used nondestructive test technique for measuring the thickness of a material from one side. It is fast, reliable, and versatile, and unlike a micrometer or caliper it requires access to only one side of the test.

Ultrasonic testing is often performed on steel and other metal sand alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is used in many industries including steel and aluminum construction, metallurgy, manufacturing, aerospace, automotive and other transportation sectors.

Positive Material Identification (PMI) is one of the more specialized non destructive testing methods. With positive material identification the alloy composition of materials can be determined. If a material certificate is missing or it is not clear what the composition of a material is, then PMI offers the solution.

Hardness Test The Metals Handbook defines hardness as "Resistance of metal to plastic deformation, usually by indentation. However, the term may also refer to stiffness or temper, or to resistance to scratching, abrasion, or cutting. It is the property of a metal, which gives it the ability to resist being permanently, deformed (bent, broken, or have its shape changed), when a load is applied. The greater the hardness of the metal, the greater resistance it has to deformation.

- Grain size

- Porosity and voids

- Phase analysis

- Dendritic growth

- Cracks and other defects

- Intergranular attack (IGA)

- Stress corrosion cracking

- Coating thickness

- Inclusion size, shape and distribution

- Case Depth

- Weld and heataffected zones (HAZ) microstructures

- Identification of deleterious inter metallic phases such as sigma

- Graphite nodularity

- Carburizing and Decarburization thickness

- Nitriding thickness

- Sensitization

- Flow-lines in forgings